lollicandy

Active Member

- Joined

- May 28, 2005

- Messages

- 1,370

- Reaction score

- 1

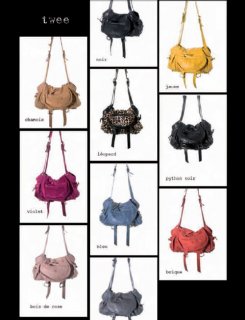

The Traveller's bag

Jérôme Dreyfuss

Taken to pieces

The bag is the thing. The young designer Jerôme Dreyfuss understands this and he is now seen as a master of an art that is as much about aesthetics as luxury. That is the reason why we have chosen him (alone) to talk about the production of a bag (for everyone). For Dreyfuss treats leather with as much attention as if it were from another human being. With the result that the leathers he takes so much care in selecting have the soft velvety quality of a baby's skin. It is well worth the time spent to investigate the humble genesis of a bag that carries the Dreyfuss monograph.

ORIGINS

His leather originates exclusively from France or England, as the provenance guarantees both the well-being of the animal and, consequentially, the quality of its hide. But when Dreyfuss uses Python leather, he sources from countries such as Indonesia or Malaysia, where the animal is not under threat of extinction.

PURIFICATION

Once the hide has been chosen, the moment arrives when it will be turned into leather at the tannery. This process is called le travail de rivière where the hide undergoes a treatment with water to eliminate the impurities and rehydrate the skin before being cured.

TANNING

Then follows the process of skinning and scudding, which aim to eliminate the grease and the hairs via the use of biocides or non-toxic enzymes... ethics are important. Following this, the hide is tanned using a vegetable tannin. Only 8% chromium is used in this operation in order to help protect the environment.

TRANSFORMATION

It is now time for the currying, which transforms the tanned hide into finished leather. It is wrung whilst still humid, the splitting is done, which consists of cutting it across to separate the croûte (outer) from the fleur (inner). Jérôme Dreyfuss works only with the fleur of leather, considered to be of superior quality since it has never been in contact with the outside world. It is then nourished with fish oil, which renders it supple and impermeable.

FINISHING

Finally, comes the dyeing. As with the tanning, Dreyfuss uses vegetable dyes, again containing only 8% chromium as opposed to the standard 80%. The skins become brick-red, chestnut, cognac, brown, nutmeg, pecan, chocolate, russet and olive coloured. Talc is powdered on them, for the sake of softness. They are then selected and arranged on the basis of their pattern. Once cut out, there is no waste, the off-cuts are used to make small leather items. The larger pieces are coloured, assembled, waxed and lined, clasps and locks are added, logos are printed on and... as we said, the case is in the bag.

from ICONOfly.com

Jérôme Dreyfuss

Taken to pieces

The bag is the thing. The young designer Jerôme Dreyfuss understands this and he is now seen as a master of an art that is as much about aesthetics as luxury. That is the reason why we have chosen him (alone) to talk about the production of a bag (for everyone). For Dreyfuss treats leather with as much attention as if it were from another human being. With the result that the leathers he takes so much care in selecting have the soft velvety quality of a baby's skin. It is well worth the time spent to investigate the humble genesis of a bag that carries the Dreyfuss monograph.

ORIGINS

His leather originates exclusively from France or England, as the provenance guarantees both the well-being of the animal and, consequentially, the quality of its hide. But when Dreyfuss uses Python leather, he sources from countries such as Indonesia or Malaysia, where the animal is not under threat of extinction.

PURIFICATION

Once the hide has been chosen, the moment arrives when it will be turned into leather at the tannery. This process is called le travail de rivière where the hide undergoes a treatment with water to eliminate the impurities and rehydrate the skin before being cured.

TANNING

Then follows the process of skinning and scudding, which aim to eliminate the grease and the hairs via the use of biocides or non-toxic enzymes... ethics are important. Following this, the hide is tanned using a vegetable tannin. Only 8% chromium is used in this operation in order to help protect the environment.

TRANSFORMATION

It is now time for the currying, which transforms the tanned hide into finished leather. It is wrung whilst still humid, the splitting is done, which consists of cutting it across to separate the croûte (outer) from the fleur (inner). Jérôme Dreyfuss works only with the fleur of leather, considered to be of superior quality since it has never been in contact with the outside world. It is then nourished with fish oil, which renders it supple and impermeable.

FINISHING

Finally, comes the dyeing. As with the tanning, Dreyfuss uses vegetable dyes, again containing only 8% chromium as opposed to the standard 80%. The skins become brick-red, chestnut, cognac, brown, nutmeg, pecan, chocolate, russet and olive coloured. Talc is powdered on them, for the sake of softness. They are then selected and arranged on the basis of their pattern. Once cut out, there is no waste, the off-cuts are used to make small leather items. The larger pieces are coloured, assembled, waxed and lined, clasps and locks are added, logos are printed on and... as we said, the case is in the bag.

from ICONOfly.com

It's lovely but I'm suprised how light the bag is. Though, the size of it suits me perfectly and I can't wait to wear it.

It's lovely but I'm suprised how light the bag is. Though, the size of it suits me perfectly and I can't wait to wear it.